Company

Home - company

Over 30 years of experience

Our dedication to quality and professionalism is the foundation on which every aspect of our work is based. We believe that quality is not a compromise, but an imperative necessity.

Founded on the basis of a deep passion for engineering and metalworking, we have earned a solid reputation throughout Europe in the industry due to our dedication to quality, proposed technical solutions and consistent service to our customers old and new.

With more than 30 years of experience behind us, we are proud to be a one-stop shop for companies seeking customized mold solutions that improve their efficiency and market competitiveness.

Our strength is our PROBLEM SOLVING ability: we accept the most difficult challenges and find the right solution for each client through a coordinated assessment with the client’s needs and a more or less in-depth feasibility study depending on the part to be performed.

We pay close attention to

every part of the processing

What differentiates us

Our dedication to quality is unsurpassed. Every mold we make undergoes rigorous quality control to ensure flawless performance and long service life. We are proud of our reputation for the accuracy and reliability of our products.

We have successfully faced a wide range of challenges and are ready to put our expertise to work for you.

- We offer our clients a feasibility study service

- We make prototypes and small batch production.

- We offer first-rate customer service.

- Your satisfaction is our top priority.

- We are always ready to listen to your needs and customize solutions according to your specific requirements.

Sustainability: Our Choice for a Better Future

In a world where environmental sustainability is a crucial priority, the company is driving change through a bold and responsible choice: the adoption of solar panels in-house. This decision not only reflects our commitment to the environment, but is also a firm step toward a greener and more sustainable future.

Solar panels, strategically placed on our site, allow us to generate clean, renewable energy directly from the sun. This solar energy not only powers our daily operations, but also allows us to reduce our dependence on nonrenewable energy sources, thus contributing to the reduction of carbon emissions.

|

Informazioni Azienda

|

Comes // Meccanica Brefa SRL

|

|---|---|

|

Production

|

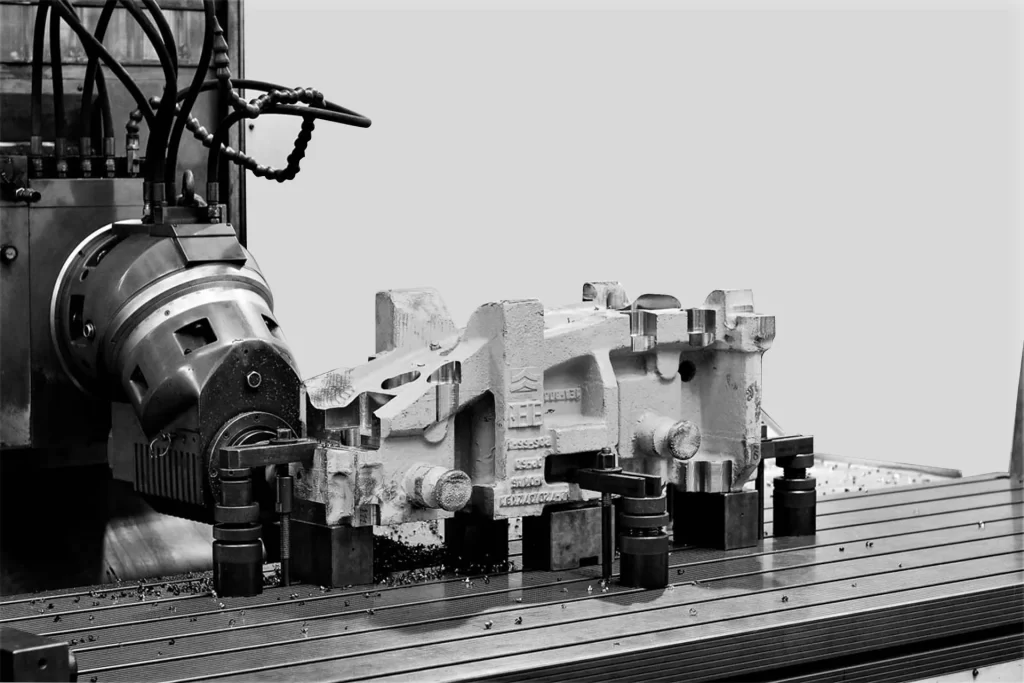

Sheet Metal dies Engineering / Design / Manufacture / Assembly and Press Tests of all tools. Tryout by end customer: Single Manual dies; Progressive Dies; Transfer; Blanking and Piercing Dies; deep Drawing; Forming Dies; machining and spare parts.

|

|

Export:

|

Export 90% of our turnover.

|

|

Language:

|

English / Italian /

|

|

Material

|

Steel / Stainless Steel/ Aluminium / Special Steel DP /High S/…etc.

|

|

Thickness:

|

from 0,5 mm up to 7 mm

|

|

Maximum Dies Dimension:

|

4300 x 1900 x 1000 mm

|

|

Press machine, production and tooling tryout

|

∙Mechanic Press from 400Ton Table 2500x1500 mm with automatic feeding line

|

|

|

∙Mechanic Press to 1000 Ton up to Table 3900x1750 mm

|

|

|

∙Hydraulic Press: 450 Ton Table 1500x2600 mm

|

|

|

∙Working Machine up to 6000 mm, 5 ton

|

|

CAD DATEN FORMAT

|

Iges, Vda, Step,dxf, Catia, SolidWorks

|

|

Comunication:

|

E-Mail – Mobile

|

|

Quality

|

Automatic 3D CMM machine table dim.2000 x 1000 mm

|

|

The process of tool manufacturing:

|

Weekly Report with photo

|

|

Heat treatment, metal finishing

|

According to customer spec. and our experience (Tin C…)

|

|

Gas Spring

|

According to customer spec. All springs must be Fibro-compatible, DIN/ISO 9182, interchangeable; Fibro-compatible

|

|

Guiding Elements

|

Bronze,with solid lubricant or steel guide bushes, bronze plated

|

|

Bushings

|

DIN/ISO required, different makes to be interchangeable

|